greenhouse pads and their prices

We have described the fan system and pads and the types of exhaust fans and their prices, we will examine the specifications of the types of greenhouse pads and their prices. Each cellulose pad is made of regular, wavy thin layers of a type of paper with capillary properties and high-water absorption. This amount of water absorption in the pad is one of the important factors in the greenhouse cooling, so that one m3 of cellulose pad is able to absorb about 100 liters of water. And of course, not carrying water droplets during the cool air entering the greenhouse is one of the most important issues that in addition to preventing the transmission of harmful bacteria, provides fresh and healthy air.

The speed of the air in the pad is three to four times the speed of the air in the straw, while due to the structure of the pad, water droplets are not carried into space. Greenhouse pads can work with water up to 48 ° C and pH between 6 and 9. The structure and formulation of greenhouse pads have made it impossible to make it in many countries. Today, due to the special technology in the production of this product, only a limited number of companies are able to produce quality cellulose pads.

Therefore, the selection and use of cellulose pads requires knowledge and experience, and the use of cellulose pads, which are only similar in appearance to the original samples, will not only deprive the customer of its benefits, but will cost them extra.

greenhouse pads

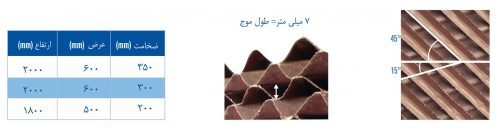

Model 7060 pad

When the layers of cellulose paper with a wavelength of 7 mm are placed on top of each other and form an angle of 60 degrees, the cellulose pad is called model 7060. This model is especially used when higher air velocities are required, such as gas turbine pre-coolers. The dimensions of this model are according to the customer’s choice and based on the capacity and dimensions of the cooling system, and usually in this model, a drain or distributor is used in the upper part of the cellulose pad. The cooling efficiency of cellulose pads model 7060 is 87% on average.

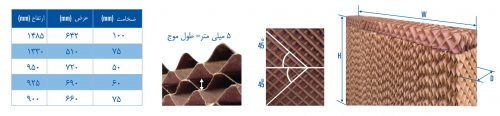

Model 5090 pad

In the case where the paper layers of cellulose pads with a wavelength of 5 mm are stacked on top of each other and form a 90 degree angle, they are called model 5090 pads. This model of cellulose pads is especially suitable for devices that supply cool air or so-called air conditioners in residential, commercial, industrial and public places. The dimensions of 5090 pads are according to the customer’s choice and based on the capacity and dimensions of the devices, and the criterion for calculating the volume and its price value is based on cubic meters.

The importance and high sensitivity of creating optimal cooling in these places (due to human presence) has caused the model 5090 pads to have a small pad at the top of the main pad for uniform water distribution so that this drain runs the risk of drying some parts and layers of the cooling pad Minimize and increase the contact surface of the weather to achieve maximum evaporation (cooling) efficiency. The efficiency of cellulose pads in model 5090 is 87% on average.

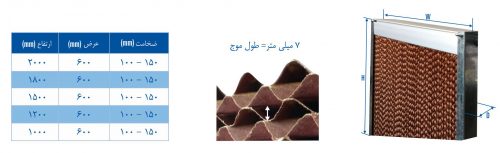

Model 7090 pad

When cellulose papers with a wavelength of 7 mm are stacked on top of each other and form a 90-degree angle, the cellulose pad is called Model 7090.

This model is used especially in the walls of greenhouses and poultry houses with a set of frames (frame and studs above and below the pad), water supply system (tank, pump and pipe) and ventilation (fan and ventilator). The dimensions of this model are according to the customer’s order and based on the capacity and dimensions of the cooling system. Evaporation efficiency (cooling) in model 7090 is 81% on average.

Calculations related to the height and length of the cellulose pad required by the greenhouse

To calculate the pad height we use the formula HP = (Fr) ÷ (LP) ÷ (Vd) in which HP pad height (meters), Fr airflow intensity or air displacement speed (cubic meters per minute), LP Pad length (meters), Vd is the design speed (meters per minute).

The intensity of air flow (Fr) depends on factors such as: – The height of the greenhouse above sea level – The intensity of light radiation – The uniformity of temperature – The distance between the pad and the fan.

Air velocity in standard conditions is obtained using the formula Greenhouse useful height Fr = L × W in which Fr is the intensity of air flow or velocity of air displacement (cubic meters per minute), L Greenhouse length (meters) W width Greenhouse (m) In the calculation of the pad system, if the efficiency of the cooling system is known, the cooled outlet temperature of the pad can be obtained by the relation TCool = TOut – (% EF) (TOut – TWB) in which TCool outlet temperature of the pad, Tout dry temperature Outside, TWB Wet Outside Temperature, EF: System efficiency (percentage). It should be noted that the efficiency of the pads is different in different weather conditions.

| Performance of pads in different weather conditions | ||||

| temperature difference | Conditions after crossing | External conditions | ||

| Δ˚C | Temperature

(˚C) |

Humidity (Percentage) | Temperature

(˚C) |

Humidity (Percentage) |

| 18.5 | 26.5 | 60 | 45 | 10 |

| 16.5 | 23.5 | 60 | 40 | 10 |

| 14 | 21 | 62 | 35 | 10 |

| 12.5 | 17.5 | 63 | 30 | 10 |

| 15 | 30 | 67 | 45 | 20 |

| 13.5 | 26.5 | 68 | 40 | 20 |

| 11.5 | 19.5 | 70 | 35 | 20 |

| 12 | 23 | 69 | 30 | 20 |

| 12 | 33 | 74 | 45 | 30 |

| 11 | 29 | 75 | 40 | 30 |

| 10 | 25 | 78 | 35 | 30 |

| 9 | 21 | 80 | 30 | 30 |

| 11 | 34 | 76 | 45 | 40 |

| 10 | 30 | 78 | 40 | 40 |

| 8 | 27 | 80 | 35 | 40 |

| 7 | 23 | 80 | 30 | 40 |

Key points for installing a greenhouse pad

– The distance between the pad and the fan should not be less than 30 meters and not more than 50 meters

– Pads should be installed in the wind direction

– Usually, the length of the pads should be considered 60 cm less than the length of the greenhouse

– The pad should not be placed in the direction and near the fan of abandoned greenhouses

Methods to increase the life of pads

Greenhouse pad Due to constant contact with water, solutes may be deposited on the pads. The useful life of cellulose pads is between 3 to 5 years, depending on the conditions of use and maintenance. To make the most of them, do the following:

- Prevent the entry of any chemical fertilizers into water tanks

- Change tank water every 3 weeks

- Circulation of several percent of the water volume of the tanks

- Use of water with EC and PH and less solutes – water quality has a great impact on the useful life of greenhouse cellulose pads, so the evaporation of saline, recycled, chlorinated, mineral water, etc. causes sediment on the pads and reduces the efficiency of this system will be

- After the summer season, be sure to drain the cooling system water, wash and dry the pads, the sediment on the outer surface of the pads will be removed more easily in this case. It is recommended to clean the deposits with a plastic brush and then wash them. This may need to be repeated in a season depending on the water quality of the area, so the higher the frequency of this operation, the less the thickness of the sediment formed on the pad and the blockage of the pad holes will be prevented.

- Do not add phosphate-containing antifouling agents or detergents to the water of the cooling system to wash the cellulose pad, as it will corrode the pads when the dandruff is removed.

- Do not turn the machine on and off too often, as this will increase the rate of scale formation on the pads.

- It is better to keep the cooling system away from direct sunlight and in the shade, but if not, create a canopy for it.

- In order to prevent the growth of fungi and algae on the surface of the cellulose pad, cut off the water supply system every 24 hours for 45 to 70 minutes until the pad is completely dry.

Some of the services of Mazrae Bekr Company related to cellulose pads:

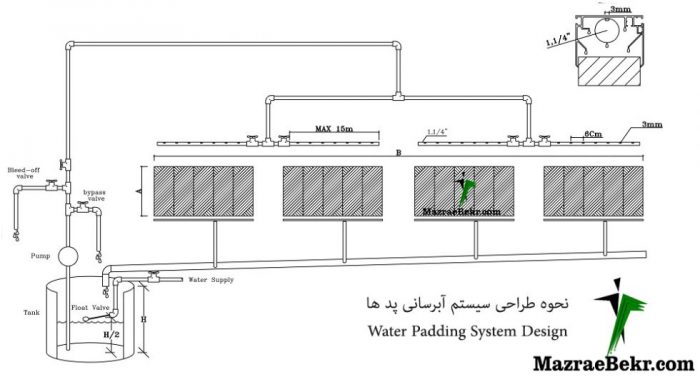

Design and presentation of fan and pad system calculations in accordance with the conditions of the region.

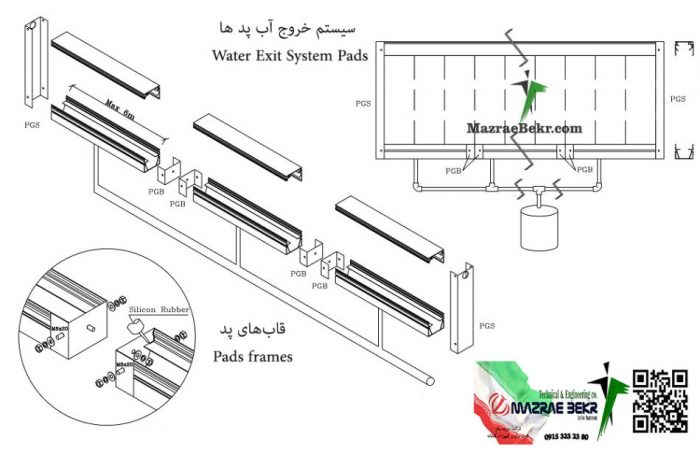

Design, production and presentation of aluminum or galvanized pad frames.

Introducing and presenting different types of greenhouse cellulose pads.

Introducing various types and providing ancillary equipment, including tanks, pumps and valves, etc.

Installation of fan and pad system

Warranty and after-sales service

Model 90 70 pad is used for evaporation cooling systems for greenhouses

to see our store click on the picture below